Light fidelity (Li-Fi) presents a fast, safe, secure alternative to radio-frequency networks.

The traditional approach to reducing network costs is using radio-frequency wireless. An alternative approach uses light fidelity (Li-Fi) instead of radio transmission. This technology can also support the world’s transformation from isolated systems to networks of Internet-enabled “things” capable of generating data that can be analyzed to extract information. Li-Fi goes beyond basic machine-to-machine (M2M) communication, and offers advanced connectivity among field devices, systems and services. Along with avoiding challenges related to physical wiring, optical wireless enhances the ability to achieve the Industrial Internet of Things (IIoT).

Li-Fi bits and pieces

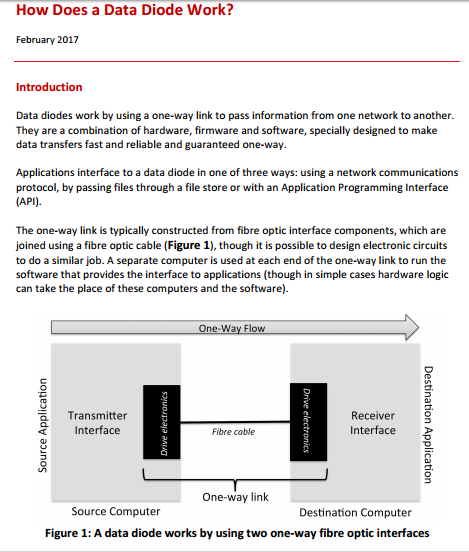

The 3rd Gen Modular Li-Fi instrument communication network consists of optical wireless field instruments, optical access point (OAP) transceiver modules and fiber-optic Ethernet converter modules installed in the field and/or transceiver modules, with multiple control network switches installed in communication cabinets or DCSs in the control room or substation (Figure 1).

Optical wireless instruments (OWI) are located inside or outside of the process module in a plant's process area to measure/control its process variables. Optical access point (OAP) transceiver modules are deployed in the ceiling of closed areas and either in the outside handrail platform or in the structure platform/grating/support for the open areas. OAPs are connected to fiber-optic Ethernet media converters via redundant Ethernet cable (copper, twisted pair, Cat5, RJ45, 8P8C) to convert fiber-optic media into Ethernet and vice versa.

Fiber-to-Ethernet media converter modules are located in the field and/or closed areas to facilitate media conversion between fiber-optics and Ethernet. Redundant fiber-optic cables are routed in separate, divergent routes to connect field-installed OAPs and control network switches in industrial control system (ICS) communication cabinets. Cabinets and DCSs in the control room or substation are connected by redundant Ethernet cables to an ICS cabinet and DCS and PLCs in the local control room (LCR), local electrical room (LER) or substation.

Li-Fi-enabled OWIs provide robustness, real-time response, reduced installation time and reduced power consumption. We've observed significant impacts from using OWIs instead of wired instruments in unclassified areas, hazardous locations and harsh, corrosive or reactive environments.

Consequences of using OWIs can also be viewed in terms of engineering/design impacts and construction/fabrication deliverable impacts (Table 1). These are major areas of concern, not only for clients, but also for EPCs, other contractors and vendors.