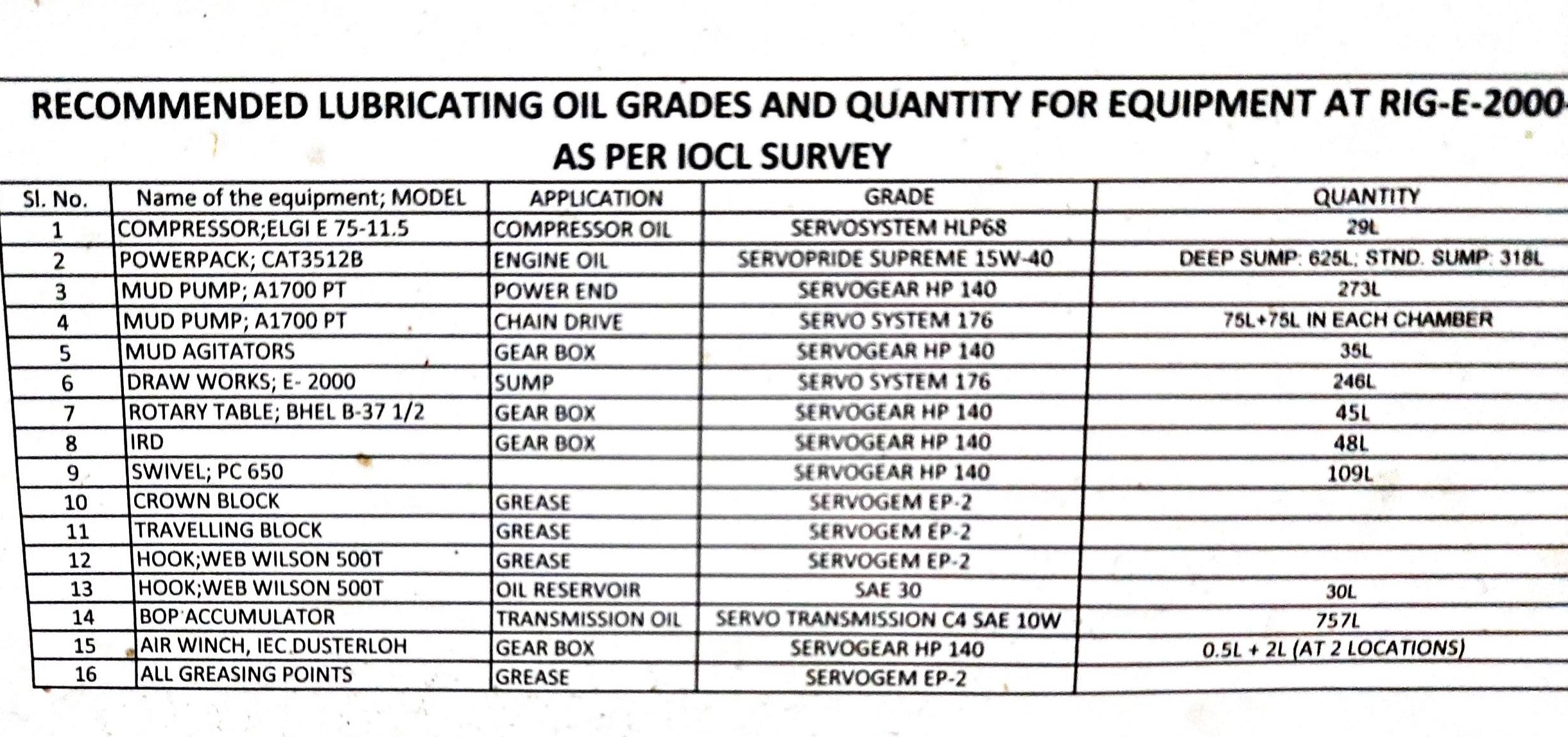

Recommended Lub oil Chart

Root Cause Analysis of Rig Equipment

Recommended Lub oil ChartModified on by GS RAO |

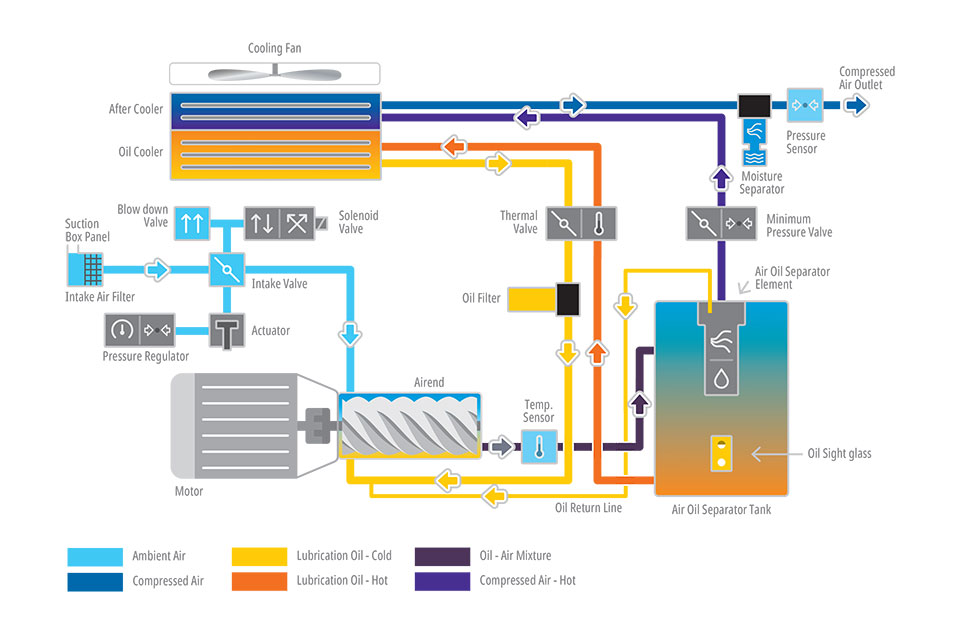

Air Pressure drop during Draworks operation. E 2009Problem: Air pressure drop during Drawworks operation.Frequent Air pressure drop obseved during pull out of the Drill pipes observed on 08.03.2020. Cheked all the airline piping from Tank for any leakages.No air leakage found. Changed the Air compressor to Compressor no.1. No Pressure fluctuations were observed.Continued the Pull out. Compressor No.2 was checked for any malfunctioning of valves by FMP-Specialist group. Air intake unlaoding valve actuator is not working. Broken spring was replaced, Tested the compressor, found ok. What went well: 1) Availability of Actuator spring & other spares. 2) Specialist group specifically targeted the comprssor problems. was quick at arriving the solution. This article may be helpful while solving various Drill Rig Eqpt problems.

|

Fluid End replacement in A-1700 PT BPCL Mud PumpsProblem: ( E-2009/LKGN)Heavy Vibrations of Middle fluid end chamber in Mud pump-1 was observed. Informed to Drilling Shift in charge & DIC to plan for action. Drill string was pulled out upto shoe as the fluid end replacement takes more time. Requested Electrical i/c to put motor under repairs Tag. Liner & Piston assy removed.Two broken studs at the bottom side of fluid end noticed. After removal of both suction and Discharge manifolds, Fluid retrieved with help of crane. With help of welder, tried to retrieve Broken studs, but no success. Another fluid end(NOV make,Fine threaded) available at site, New Brass adapter fitted, Replaced the same. Major shutdowns could be averted with help of Fine threaded fluid end and High strength Stud bolts, which can with stand higher loads for long period. What went well:

Drilling operations resumed. May be this article helpful for the people who are attending Rig Equipment Mechanical maintenance jobs. |

Draw works: Broken Relay valve at E 2009 #LKGNProblem: Heavy Air Leakage and Non functioning of Hi/Lo Clutch during Retrieval of Pull out of Drill pipes at 2450 mtr. Observed Heavy air leakage from Relay valve input pipe(Damaged Relay valve fount at the bottom water sump). Ball valve is used to shut the air, Lo Clutch functionality resumed.Started Pull out of Drill pipes before casing. Relay Valve and control piping put back in place, Full functionality of Lo/Hi Clutch returned. Interlock relay valve also Lubricated & checked before testing of Draw works. Shut down was avoided, Safe retrieval of Drill String also before casing, which was planned in the subsequent day, Casing also completed as per schedule. Article may be helpful. |

-

1

-

Results per page